Conveyor & Tunnel Metal Detection Systems

Future-proof compliance for inline packaged and unpackaged products

Conveyorized metal detection systems wiithin our range of rectangular tunnel in-line metal detectors are designed to fit your budget and performance needs. These fully automated systems can detect and reject ferrous and non-ferrous metals, as well as hard-to-detect grades of stainless steel. Meet compliance requirements with a single-supplier solution to your food and non-food processing challenges.

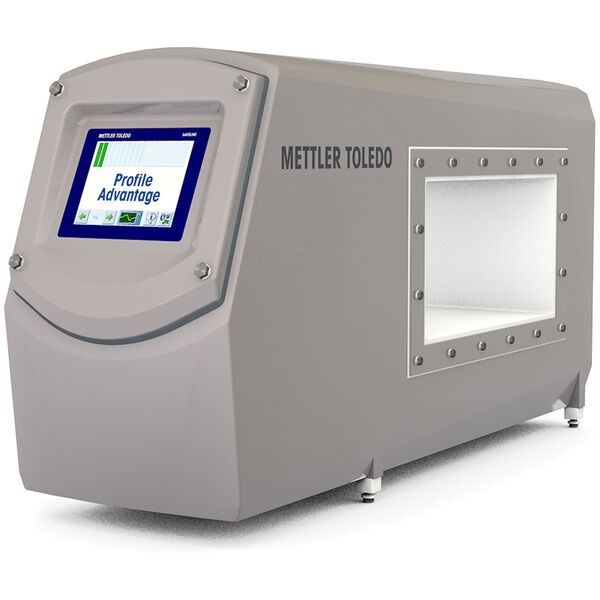

Profile Advantage Metal Detector

Der fortschrittlichste Lebensmittel-Metallsucher von Safeline, der eine um bis zu 50 Prozent höhere Empfindlichkeit bei der Inspektion feuchter, heißer, gekühlter, tiefgefrorener oder in Metallfolie verpackter Produkte bietet.

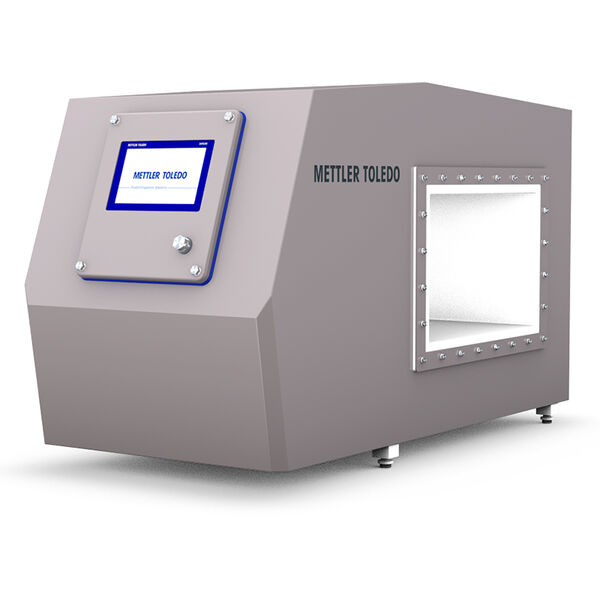

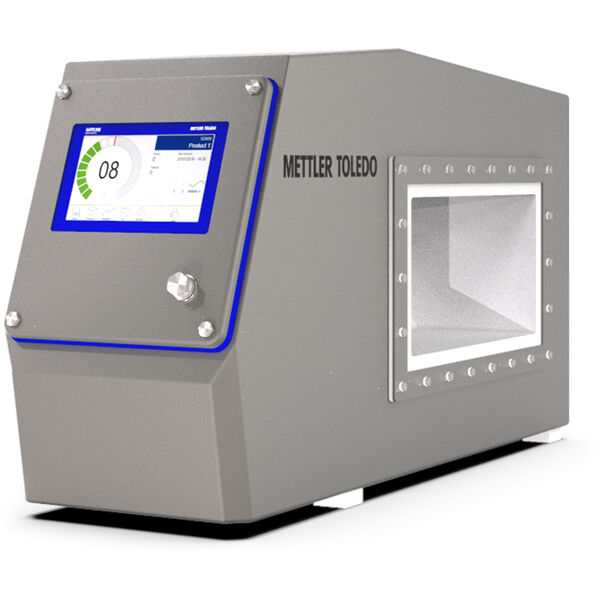

Metal Detector M31R

Industrielle Metallsuchgeräte der nächsten Generation bieten hohe Empfindlichkeit bei einfacher Bedienung, um eine erschwingliche Qualitätskontrolle zu gewährleisten. Geeignet für die Inspektion trockener oder feuchter Produkte.

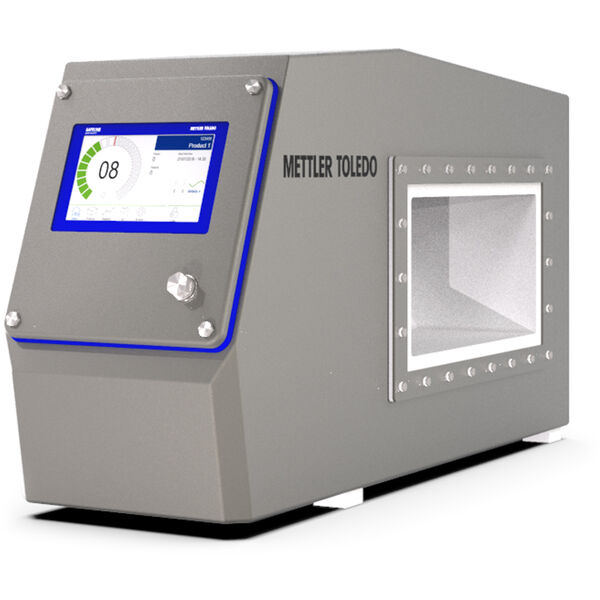

Metal Detector M33R

Industrielle Metallsuchgeräte der nächsten Generation bieten ein deutlich höheres Leistungsniveau und eine sehr hohe Empfindlichkeit. Geeignet für die Inspektion trockener oder tiefgefrorener Produkte.

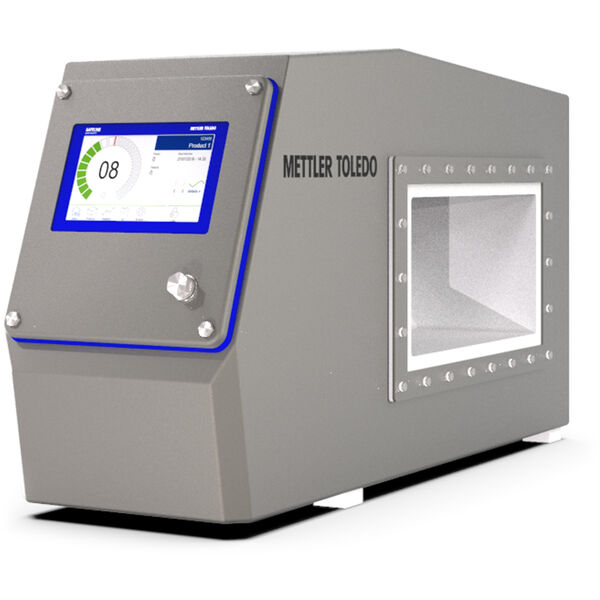

Metal Detector M34R

Industrielles Metallsuchgerät der nächsten Generation mit DSF-Technologie (Dual-Simultaneous Frequency) mit sehr hoher Empfindlichkeit. Ideal für die Inspektion feuchter oder in Metallfolie verpackter Produkte.

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

New Remote Support

Keeping Your Production Running

In addition to our existing 24/7 technical phone support, we offer the latest in remote service support using Augmented Reality (AR) technology. This allows us to provide the quick expert support you need to achieve your productivity goals.

Our METTLER TOLEDO augmented reality-powered visual remote assistance solution helps us to fully understand your service issues. Using a mobile device with an integrated camera enables us to see exactly what you see. We can guide you step-by-step to resolve the issue by providing real-time contextual assistance, such as adding text, drawings, or highlighting objects with 3D markers. Benefit from the fastest fault diagnostics, repair, and part replacement support by using the latest technology. We can also remotely connect to some of our products for additional service enhancement. Please contact your local service team for more details.

Explore our Services

Uptime. Support & Repair

Performance. Maintenance & Optimization

Compliance. Calibration & Quality

Expertise. Training & Consulting

- Bakery Production Metal Detection

- Gravity Fall Metal Detectors

- Industrial Metal Detector for Agriculture

- Industrial Metal Detector for Cosmetics

- Industrial Metal Detector for Flour and Grain Industry

- Industrial Metal Detector for Meat Processing

- Industrial Metal Detector for the Chemical Industry

- Industrial Metal Detectors for Plastics

- Industrial Metal Detectors for the Dairy Industry

- Industrial Metal Detectors for the Seafood Industry

- Industrial Metal Detectors for the Sugar Industry

- Metal Detection in Ready Meals

- Metal Detection Technology for Snacks and Confectionery

- Metal Detector for Ferrous and Non-Ferrous Metals

- Metal Detectors for Food Processing

- Metal Detectors for Meat, Poultry and Seafood Production

- Metal Detectors for Pet Food

- Metal Detectors for Pulp and Paper

- Metal Detectors for the Food Industry

- Pharmaceutical Metal Detectors

- Pipeline Metal Detectors

- Throat Metal Detectors

FAQs

How does a conveyorized tunnel metal detection system work?

A conveyor is integrated with a tunnel metal detector to allow the product to pass through the aperture of the metal detector and be inspected for metal contaminants.

METTLER TOLEDO Safeline provides a range of industrial metal detectors for detecting ferrous and non-ferrous metals, including the difficult to detect grades of stainless steel, designed to suit your specific inspection and budget needs.

Our conveyor systems have an automatic reject device fit to the transport system in order to swiftly and effectively remove any contaminated product from the production line. There are many different reject mechanisms available including:

- Air blasts

- Push arms

- Lift / drop flaps

The type of the reject mechanism installed will depend on the product or packaging type being inspected. You can choose from a range of industrial metal detector conveyor belt types, system integration widths & lengths, and failsafe monitoring features to provide a flexible solution to meet production needs.

The metal detector, transport system, reject device and a suite of integrated sensors work in harmony so products contaminated with metal can be efficiently detected, rejected, and removed from the production process.

Conveyorized tunnel metal detection systems are also known as in-line metal detectors, rectangular aperture detectors (RAD) and rectangular tunnel metal detectors.

How do I choose the right metal detector conveyor system?

The first step is to choose the right metal detection technology for your application. METTLER TOLEDO Safeline offers an extensive range of options, from tuned frequency technology for dry products, to Dual-Simultaneous and Multi-Simultaneous frequency for products that are wet, hot, chilled, cooling or packed in metalized film. Proprietary innovations including Boost mode, eDrive™ and advanced algorithms increase sensitivity performance and minimize false rejects. Additionally, Enhanced Noise Immunity (ENI) and Enhanced Vibration Immunity (EVI), along with Dynamic Stability Control innovations deliver exceptional reliability in the most challenging production environments.

The design of both the metal detector conveyor belt and the reject mechanism can have a major impact on the effectiveness of your overall metal detection program.

A wide range of standard and customized metal detector conveyor systems are available. Each system is tailored to suit specific production needs, from inspecting unpackaged or bulk products to packaged products in a variety of sizes. With METTLER TOLEDO Safeline metal detectors, customers can also choose from several compact solutions for small spaces. Our GC Series is a modular conveyor system suitable for a wide range of conveyorized light to heavy product applications. We design and manufacture our systems in-house, so custom systems can be built to your exact requirements.

What accessories and equipment are available with industrial conveyorized metal detectors?

In addition to the different reject mechanisms available, other equipment and accessories may include:

- Lockable containers to collect and hold rejected product

- Full-length covers between the detector and the reject mechanism

- Failsafe alarms to alert metal detector faults

There are several additional optional failsafe systems to raise the level of due diligence for manufacturers. Our industrial metal detector conveyor belt systems can be tailored to suit specific inspection requirements, including but not exclusively:

- A choice of aperture sizes

- Reject mechanisms

- Failsafe system components

- Conveyor belt materials

- Connectivity options

Which environments are conveyorized metal detection systems suitable for?

Our conveyorized metal detector systems are suitable for almost any environment, from industrial metal detectors for packaging for inspecting dry and packaged products, to metal detectors to inspect wet, chilled, and frozen products in extreme environments. We can also supply special solutions for inspecting bulk products in hazardous locations, with metal detector heads certified to comply with ATEX / IECEx and HazLoc regulations.

METTLER TOLEDO Safeline's conveyorized metal detection systems can be configured with heavy-duty stainless steel detectors rated at IP69K, and integrated with rugged, heavy-duty conveyor frames sealed up to IP69K standard.