Integrated Product Inspection Solutions

Combination Product Inspection Systems for Every Application

Sophisticated product inspection solutions combining checkweighing with metal detection, x-ray inspection or vision inspection. Available in various degrees of compatibility with a wide range of available options which allow you to create a custom combination system to meet your requirements.

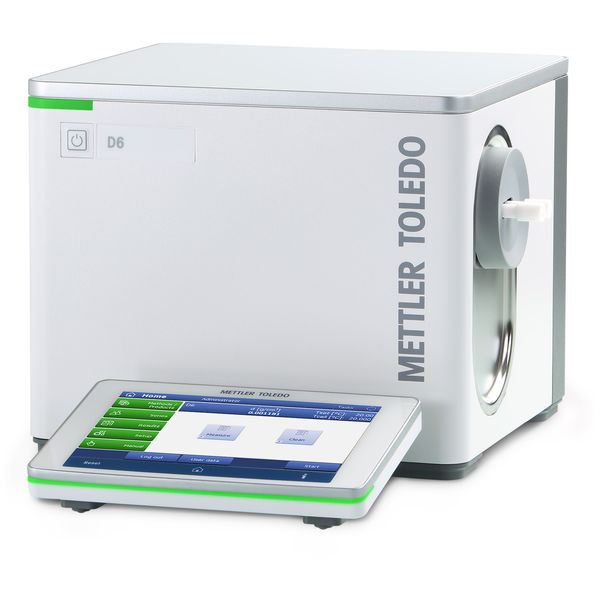

Density meter Excellence D6

Accurate, intuitive, and modular, the Excellence D6 offers fast measurements with automatic temperature control, a real-time video view of the measuring cell and automatic viscosity correction. Everything via an incredibly easy-to-use user interface.

Density meter Excellence D5

Accurate, intuitive, and modular, the Excellence D5 offers fast measurements with automatic temperature control, a real-time video view of the measuring cell and automatic viscosity correction. Everything via an incredibly easy-to-use user interface.

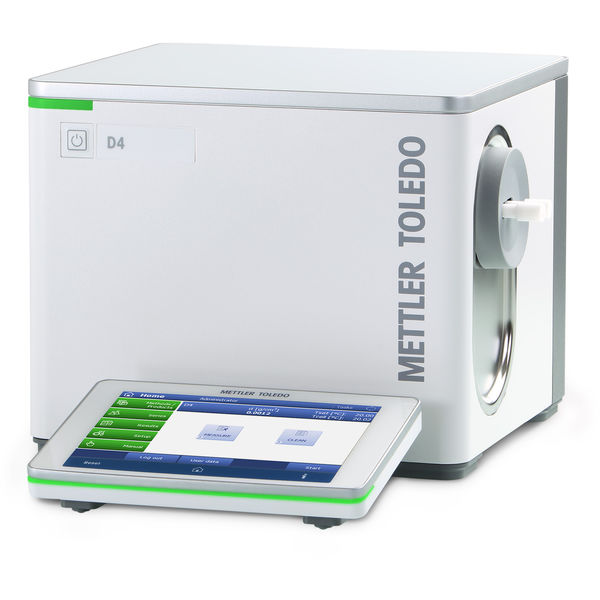

Density meter Excellence D4

Accurate, intuitive, and modular, the Excellence D4 offers fast measurements with automatic temperature control, a real-time video view of the measuring cell and automatic viscosity correction. Everything via an incredibly easy-to-use user interface.

Handheld Density Meter DensitoPro

Made for use in the lab and on-the-go, the DensitoPro is perfect for all kinds of applications, from quality control of incoming goods to at-line quality assurance. With the built-in RFID and barcode scanner, full sample identification is performed automatically.

Maximice el retorno de la inversión garantizando una instalación profesional y un paquete de cuidado adecuado

Maximice el retorno de la inversión garantizando una instalación profesional y un paquete de cuidado adecuado

Nuevo soporte remoto

Mantenemos su producción ininterrumpida

Además de nuestro soporte técnico telefónico ininterrumpido actual, ofrecemos lo último en soporte técnico remoto mediante tecnología de realidad aumentada (RA). Esto nos permite seguir ofreciendo el soporte rápido de expertos que necesita para lograr sus objetivos de productividad.

Nuestra solución de asistencia remota visual con realidad aumentada de METTLER TOLEDO nos ayuda a entender por completo sus problemas de servicio técnico. El uso de un dispositivo móvil con una cámara integrada nos permite ver lo mismo que usted. Podemos guiarle paso a paso para resolver el problema ofreciéndole asistencia contextual en tiempo real, como añadir texto, dibujos o resaltar objetos con marcadores en 3D. Benefíciese del soporte más rápido de diagnóstico de fallos, reparación y sustitución de piezas con el uso de la tecnología más reciente. Podemos conectarnos de forma remota a algunos de nuestros productos para conseguir unas mejoras adicionales del servicio. Póngase en contacto con su equipo de servicio técnico local para obtener más información.

Descubra nuestros servicios

Tiempo de actividad. Soporte y Reparación

Rendimiento. Mantenimiento y Optimización

Conformidad. Calibración y Calidad

Experiencia. Formación y Consultoría

FAQs

What is a combination checkweighing x-ray inspection product inspection system?

A checkweighing and x-ray inspection combination system is made up of two product inspection systems - a checkweigher and an x-ray detector. These systems work together to check for accurate weight, foreign contamination, and quality control inspection including completeness checks.

The inline x-ray inspection system can detect and reject products contaminated with foreign objects such as glass, metal, plastic, high-density rubber and calcified bone from the production line, which in turn can protect consumers, safeguard brand reputation, minimize the risk of expensive product recalls, and assist with regulatory compliance.

The inline checkweigher checks that each product on the line meets the minimum weight requirement to comply with global weights and measures regulations and helps to minimize costly product giveaway.

What are the benefits of using a combination checkweighing x-ray inspection system?

By using a combination x-ray and checkweighing inspection system, you protect your customer and your brand while saving valuable space on your product line. METTLER TOLEDO’s checkweighing and x-ray inspection combination systems are all-in-one inline solutions made for products up to 10kg, for fast weight data capture and reliable detection of foreign bodies. Sophisticated product handling options available on the checkweigher can be used to guide products of all shapes and sizes safely through the heavy curtain of the x-ray.

Additional benefits include:

- Separate rejection of under- and overweight products and products with foreign body contamination

- High sensitivity detection of small-sized contaminants such as shards of glass, small pieces of metal, calcified bone, and high-density rubber and plastic

- Ideal for use as a Critical Control Point (CCP) in production and packaging lines

- Reduces product waste and helps with meeting compliance requirements with global regulatory standards

- MID certifiable and highly customizable

Why is product handling important for combination checkweighing and x-ray inspection systems?

Product handling plays a critical role for inline checkweighing because true precision weighing can only be carried out if products are smoothly transported across the weighing conveyor. In addition, guiding tall or lightweight products safely through the heavy curtain of an x-ray inspection system can prove difficult due to risk of tipping over.

Combining the x-ray system with a checkweigher allows you to use the product handling options available with the checkweigher to safely secure your item prior to it passing through the x-ray system.

METTLER TOLEDO Garvens and Hi-Speed Checkweighers offer an immense range of highly sophisticated and future-resistant product handling options which are specifically designed to manage manufacturers’ ever-evolving packaging types.

What types of integrated checkweighing and x-ray product inspection solutions are available?

METTLER TOLEDO offers a diverse range of checkweighing x-ray inspection combination product inspection systems, comprised of our C35 Checkweigher in combination with one of the following x-ray inspection systems:

X33

Designed for ease-of-use, the X33 safeguards consumers and brands with its high detection capabilities and helps reduce Total Cost of Ownership (TCO) with a low energy consumption. The X33 is a compact, easy-to-use, high level detection x-ray solution ideal for single-lane inspection.

X34:

Designed for high throughput, single lane applications, the X34 provides the ultimate in product safety with a minimal False Reject Rate (FRR). It offers automated product set-up coupled with intelligent software to maximize production uptime, reduce manufacturing costs, and enhance detection sensitivity.

X36:

The X36 system consistently provides the highest levels of contaminant detection sensitivity while simultaneously performing a number of brand protection quality checks such as Product in Seal Detection.

In addition, all x-ray quality inspections are completed using only 1/5th the energy used by traditional x-ray systems.