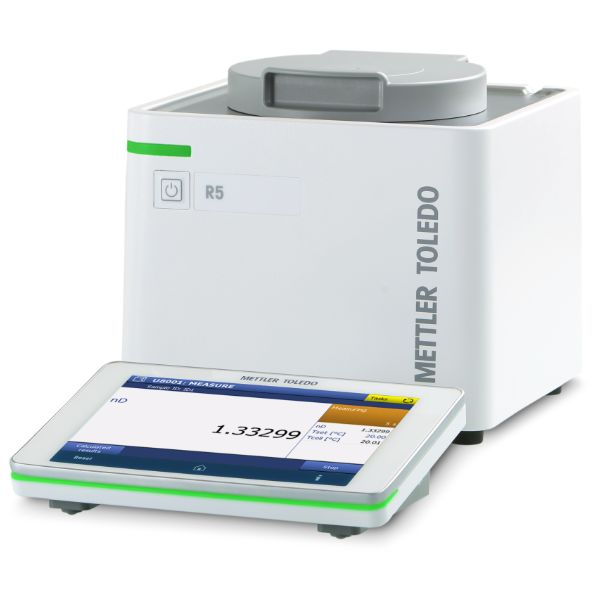

Refractometer Excellence R5

Top instrument for a wide range of applications: The Excellence R5 refractometer offers fast refractive index measurements in the range from 1.32 to 1.58, with automatic temperature control from 5 to 75°C.

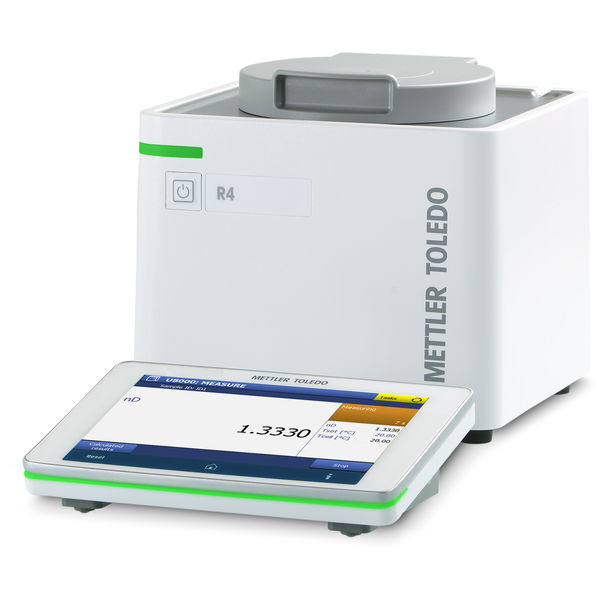

Refractometer Excellence R4

The all-rounder for daily routines: The Excellence R4 refractometer offers fast refractive index measurements in the range from 1.32 to 1.70, with automatic temperature control from 0 to 100°C.

Refractive Index Cell RX5

The RX5 Refractive Index Cell can be added to an Excellence Density meter to measure density and refractive index simultaneously. The RX5 measures the refractive index in the range from 1.32 to 1.58, with automatic temperature control from 5 to 75°C.

Refractive Index Cell RX4

The RX4 Refractive Index Cell can be added to an Excellence Density meter to measure density and refractive index simultaneously. The RX4 measures the refractive index in the range from 1.32 to 1.70, with automatic temperature control from 0 to 100°C.

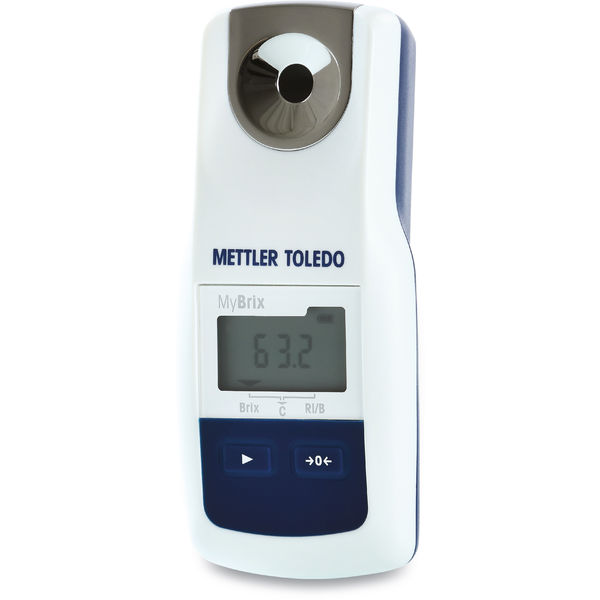

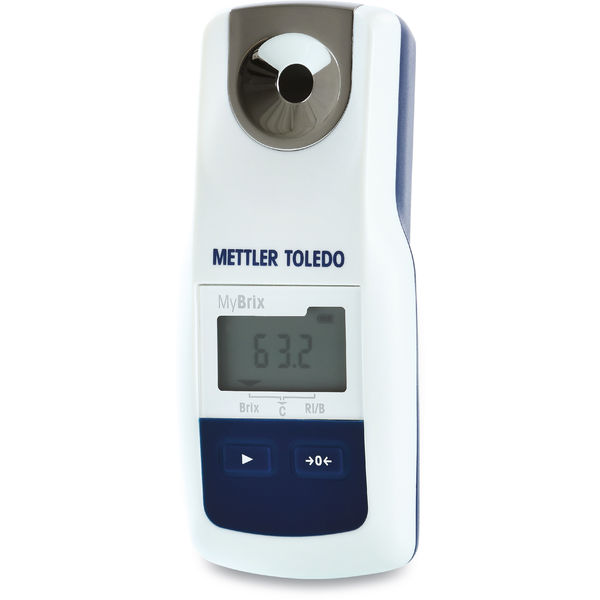

Handheld Refractometer MyBrix

With a full Brix range and 10 integrated sugar-related scales, the MyBrix offers fast measurements of almost any food and beverage sample. A compact, robust, and weatherproof design makes this portable device ideal for field and on-site measurements.

Handheld Refractometer MyBrix 10pcs box

With a full Brix range and 10 integrated sugar-related scales, the MyBrix offers fast measurements of almost any food and beverage sample. A compact, robust, and weatherproof design makes this portable device ideal for field and on-site measurements.

Maximize Your Return on Investment with Professional Service Solutions

Maximize Your Return on Investment with Professional Service Solutions

New Remote Support

Keeping Your Production Running

In addition to our existing 24/7 technical phone support, we offer the latest in remote service support using Augmented Reality (AR) technology. This allows us to provide the quick expert support you need to achieve your productivity goals.

Our METTLER TOLEDO augmented reality-powered visual remote assistance solution helps us to fully understand your service issues. Using a mobile device with an integrated camera enables us to see exactly what you see. We can guide you step-by-step to resolve the issue by providing real-time contextual assistance, such as adding text, drawings, or highlighting objects with 3D markers. Benefit from the fastest fault diagnostics, repair, and part replacement support by using the latest technology. We can also remotely connect to some of our products for additional service enhancement. Please contact your local service team for more details.

Explore our Services

Uptime. Support & Repair

Performance. Maintenance & Optimization

Compliance. Calibration & Quality

Expertise. Training & Consulting

FAQs

What is the difference between an OCV system and an OCR system?

Optical Character Recognition (OCR) is a method for identifying printed characters on a package surface. OCR is ideal for variable text fields, where it may not be possible to know what text string will be on the production line. The tool compares a given character image against all the characters in a pre-defined font to find the closest match.

Optical Character Verification (OCV), on the other hand, is looking for a pre-defined value – it is used to check for the accuracy of a code rather than determine what a code is.

OCV and OCR technology can be used in manufacturing facilities for quality checks - for example, as part of a product inspection program that includes package data quality inspection in the food and beverage industry. Machine vision inspection manufacturers such as METTLER TOLEDO CI-Vision offer vision inspection systems with OCV and OCR capabilities for printed data and code verification requirements.

Can OCV systems from METTLER TOLEDO handle variations in label materials or printing processes?

METTLER TOLEDO OCV systems are designed for versatility. They have the flexibility handle the diverse materials and printing methods encountered in real-world production lines. They can be configured to account for variations in label materials, such as the reflectivity of glossy labels or the texture of shrink wrap sleeves. Additionally, the systems can be programmed to accommodate different printing processes, whether it's inkjet, laser, or thermal printing, for consistent and reliable label data inspection every time.

Can OCV systems be used to collect data for label optimization?

Yes, OCV systems can be a valuable tool for data collection. By analyzing the types of label defects that are detected during production, recurring issues can be quickly identified, and labeling processes can be adjusted and optimized to minimize future errors. This data-driven approach can lead to cost savings, boosted productivity, and improved label quality.

Do OCV systems offer multi-language capabilities for label inspection?

Our OCV systems feature advanced character recognition software. This allows them to recognize and inspect labels with text in any language, catering to a globalized market and providing accurate inspection regardless of the language used.