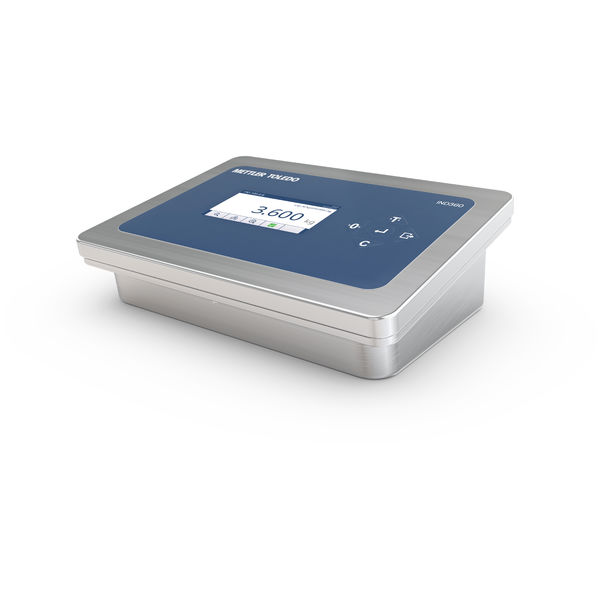

The IND360 weight indicator offers flexibility for integration with process equipment at multiple levels by allowing you match the enclosure to the application with a choice of four enclosure types: DIN-rail mount, panel mount, harsh/desk/wall mount and DIN rail with separate display.

IND360 offers a variety of pre-programmed ready-to-use weighing applications like tank/vessel level control and filling/dosing control. The IND360 weight indicator can be configured in three ways via keypad, web interface and PLC.

The IND360tank/vessel level-control application combined with the indicator’s graphical display provides clear visibility on the process status, determines the filling level of the container and triggers an automatic refill when needed.

Easily build a high-performance filling or dosing system with the fill/dose application. It is highly configurable and offers advanced functions such as self-optimization, automatic jog and a well-defined state machine.

Efficient integration is supported with device description files of major automation protocols. Sample programs such as Add-on Profiles for Rockwell and function blocks for Siemens enable a quick start in obtaining data.

Take maximum advantage of decentralized control to execute your process: the optional applications for tank level control and filling execute dedicated tasks autonomously. IND360 comes also with integrated comparators and DIO capabilities for ultra-high speed control.

IND360 incorporates Smart5™ alarms according to NAMUR NE 107 standards, providing categorized status information of the weighing system and clear actions for the user in case of issues.