Industrial Metal Detectors for the Dairy Industry

Dairy industrial metal detectors for enhancing quality control and safety in dairy applications

We provide advanced industrial metal detectors for the dairy industry, to inspect your dairy food applications and reject metal contaminants from the production line. Our fully automated metal detection systems can detect ferrous and non-ferrous metals, including non-magnetic stainless steel, and virtually eliminate false rejects. Our dairy industrial metal detectors can help you achieve compliance with various food standards and protect your consumers with improved quality control.

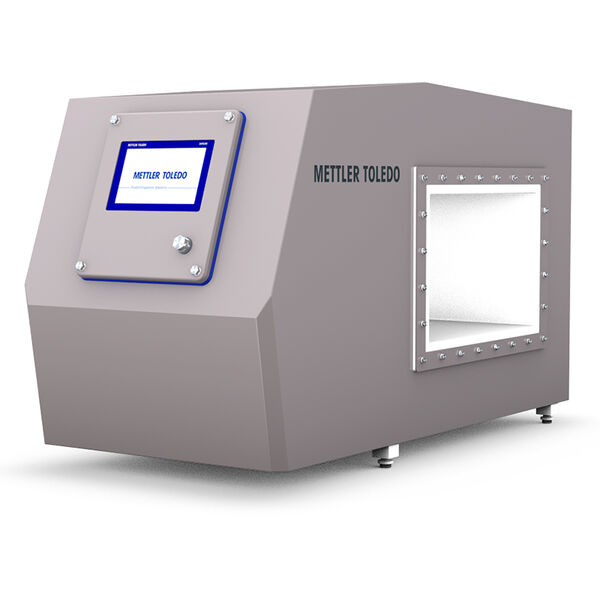

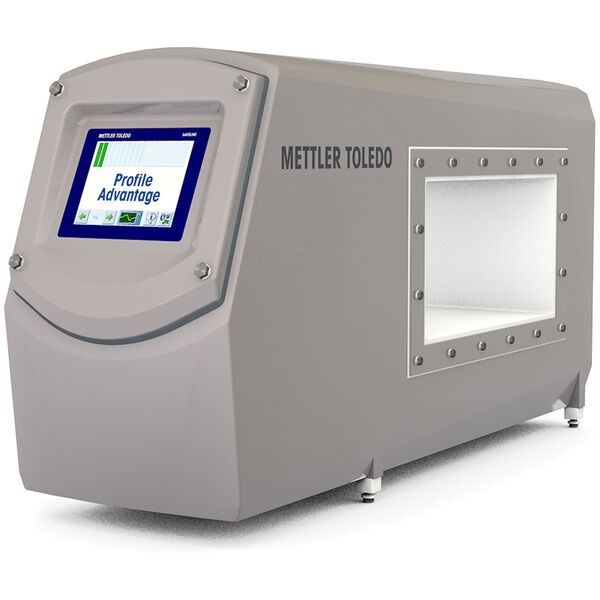

Profile Advantage Metal Detector

Safeline's most advanced food metal detector, which delivers up to 50 percent improved sensitivity when inspecting wet, hot, chilled, cooling, or metal film-packed products.

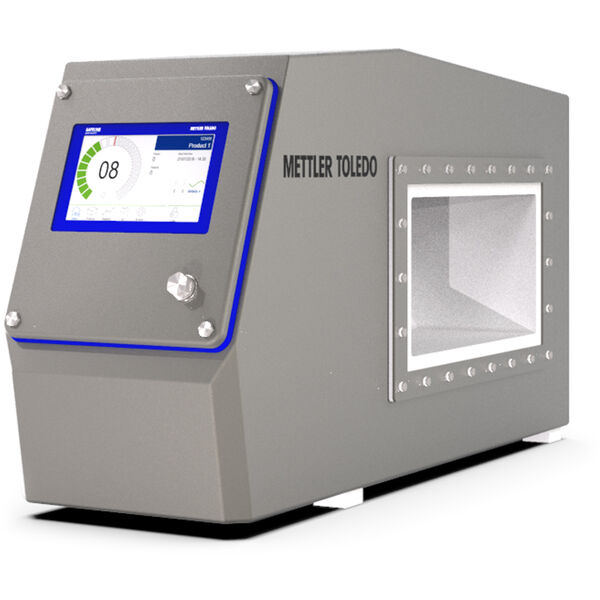

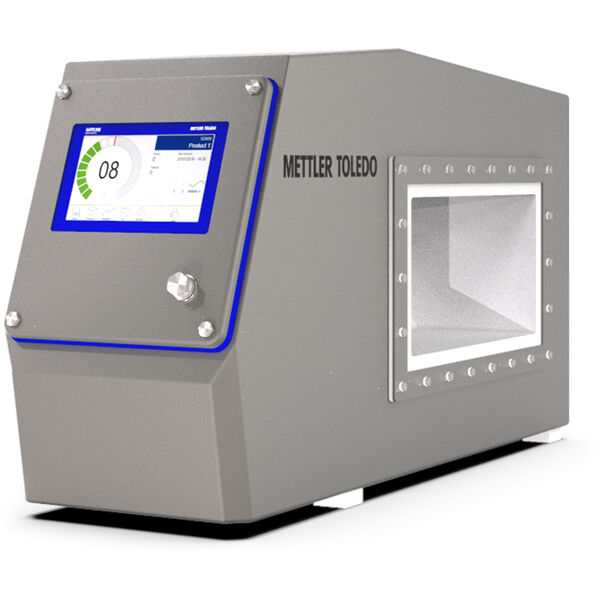

Metal Detector M31R

Next generation industrial metal detector delivers high sensitivity with ease of use to deliver affordable quality control. Suitable for dry or wet product inspection.

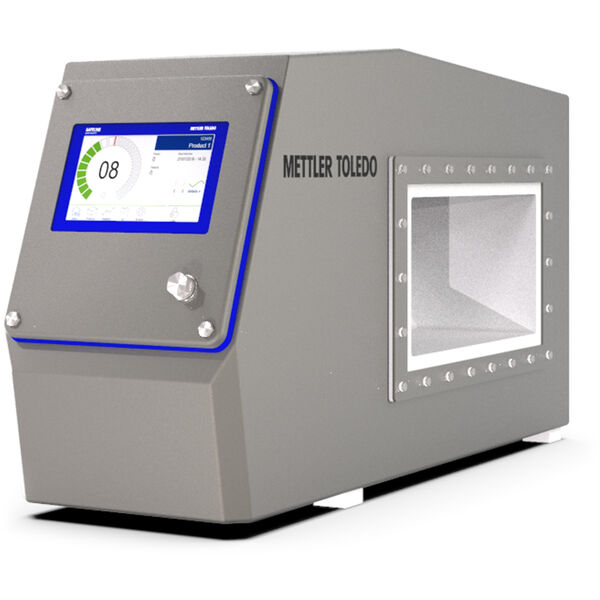

Metal Detector M33R

Next generation industrial metal detector offers a step-change in performance and very high sensitivity. Suitable for dry or deep frozen products inspection.

Metal Detector M34R

Next generation industrial metal detector with Dual-Simultaneous Frequency (DSF) technology offering very high sensitivity. Ideal for wet or metal film-packed products inspection.

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

New Remote Support

Keeping Your Production Running

In addition to our existing 24/7 technical phone support, we offer the latest in remote service support using Augmented Reality (AR) technology. This allows us to provide the quick expert support you need to achieve your productivity goals.

Our METTLER TOLEDO augmented reality-powered visual remote assistance solution helps us to fully understand your service issues. Using a mobile device with an integrated camera enables us to see exactly what you see. We can guide you step-by-step to resolve the issue by providing real-time contextual assistance, such as adding text, drawings, or highlighting objects with 3D markers. Benefit from the fastest fault diagnostics, repair, and part replacement support by using the latest technology. We can also remotely connect to some of our products for additional service enhancement. Please contact your local service team for more details.

Explore our Services

Uptime. Support & Repair

Performance. Maintenance & Optimization

Compliance. Calibration & Quality

Expertise. Training & Consulting

- Bakery Production Metal Detection

- Conveyor & Tunnel Metal Detection Systems

- Gravity Fall Metal Detectors

- Industrial Metal Detector for Agriculture

- Industrial Metal Detector for Cosmetics

- Industrial Metal Detector for Flour and Grain Industry

- Industrial Metal Detector for Meat Processing

- Industrial Metal Detector for the Chemical Industry

- Industrial Metal Detectors for Plastics

- Industrial Metal Detectors for the Seafood Industry

- Industrial Metal Detectors for the Sugar Industry

- Metal Detection in Ready Meals

- Metal Detection Technology for Snacks and Confectionery

- Metal Detector for Ferrous and Non-Ferrous Metals

- Metal Detectors for Food Processing

- Metal Detectors for Meat, Poultry and Seafood Production

- Metal Detectors for Pet Food

- Metal Detectors for Pulp and Paper

- Metal Detectors for the Food Industry

- Pharmaceutical Metal Detectors

- Pipeline Metal Detectors

- Throat Metal Detectors

FAQs

What type of dairy products can industrial metal detectors inspect?

Our industrial metal detectors for the dairy industry can be used in a variety of dairy manufacturing applications to inspect for metal contamination. They can inspect dairy products that are wet, hot, liquid, or chilled, or are packaged in a metalized film, deep-frozen, and bulk.

To help optimize the effectiveness of your inspection, you can explore the range of metal detectors we offer that are suited for each type of dairy product.

This includes gravity-fall metal detectors for free-falling products, conveyor belt systems for dairy products running on a conveyor belt, and pipeline metal detectors for liquids and pastes.

How sensitive are dairy industrial metal detectors?

We specialize in a range of industrial metal detectors for the dairy industry. The type of product you are inspecting will determine which metal detection system will provide the optimum sensitivity for inspecting your dairy product.

Sensitivity of the metal detector can be impacted by a number of factors which you will need to consider before choosing your preferred metal detection system. These include:

- The size and shape of the metal contaminants

- The state of the dairy products (deep-frozen, packaged, non-packaged, hot, liquid, dry, chilled)

- The orientation of the product as it moves through the metal detector

- The size of the metal detector aperture

Why are industrial metal detectors for the dairy industry important for manufacturing?

Our dairy industrial metal detectors are important to include in your dairy manufacturing process, as they can provide:

Enhanced quality control

Using our industrial metal detector for the dairy industry can help you reduce the risk of metal-contaminated dairy products reaching the market. Our precise metal detectors can inspect and reject various metal contaminants from dairy applications with high accuracy.

Support for industry compliance

Dairy products and the manufacturing process should aim to comply with various industry standards. Our metal detectors are designed to help you achieve compliance using our advanced technology. This includes supporting compliance with the Global Food Safety Initiative (GFSI) and the Food Safety Modernization Act (FSMA)

Maximized efficiency and minimized waste

Our dairy industrial metal detectors can drive production efficiency, and inspect products as promptly and effectively as necessary. As well as this, our reject devices – such as reject arms and photogated blasts – are designed to minimize wastage of uncontaminated product.

Product Recalls Prevention with Metal Detection

Using industrial metal detection systems in your dairy production lines can help minimize the risk of product recalls by alerting you to any potential metal contamination issues before the product reaches the consumer.