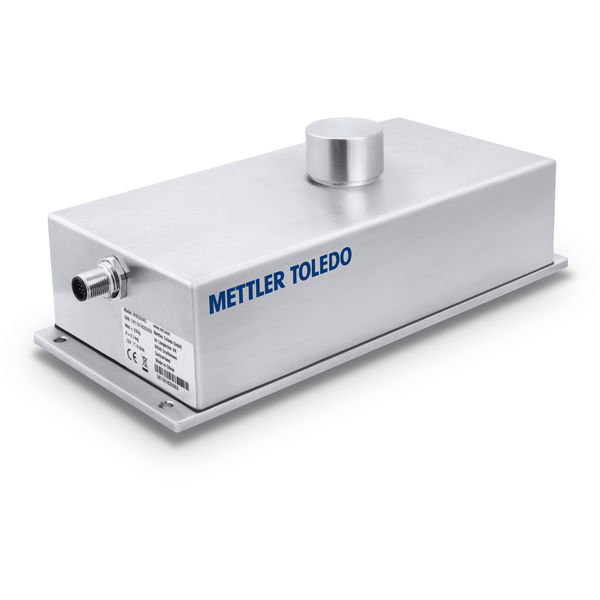

Analytical Sensor Cleaning and Calibration Systems EasyClean 500

Why do manual sensor maintenance if you don't have to? The EasyClean 500 is a compact sensor cleaning and calibration system for fully automated routine maintenance of pH sensors. Six standard programs and two customizable programs ensure operators can configure the system to their exact needs