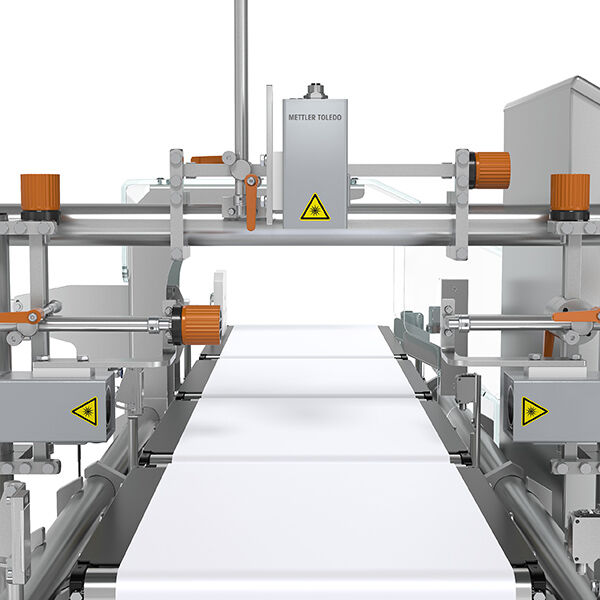

CMV Combination

Effective 3-in-1 Inspection Solution.This powerful critical control point delivers metal detection, weight control, and label inspection in one, fully integrated and space-saving device. With full configuration flexibility, this system can be designed to match your application needs.

Configuration Flexibility

Choose your system components from a range of metal detectors, checkweighers, and label inspection systems to exactly fit your application needs.

Space-Saving Design

This solution maximizes production space and enables easy cleaning and maintenance access with only four feet on the ground for increased efficiency.

Reduced Total Cost of Ownership

Benefit from a single provider to deliver configuration support, training and service for three technologies, reducing time, cost and downtime.

Material No.: 2499000200

Features

Specifications

Specifications - CMV Combination

| Reading Devices | Smart Camera |

| IP Rating | IP54 IP65 |

| Compatible Software | ProdX |

| Connectivity | Ethernet TCP/IP Fieldbus OPC UA |

| Weighing Technology | EMFR Strain Gauge |

| Product Flow | Conveyor |

| Inspection Application | Code Inspection Contamination Detection Label Inspection Weight Control |

| Product Characteristic | Deep Frozen Dry Medium-Large Packages Open Round Container Small Individual Wrapped Products Wet |

| Industry | Chemical Food & Beverage Pharma & Biotech |

| Max Product Height | 200 mm |

| Industry Segment | Automotive Bakery and Confectionery Beer, Wine and Other Alcoholic Beverages Cosmetics Dairy Fine and specialty chemicals Food Additives Meat & Poultry & Seafood Nutraceuticals Oils and Fats Pet Food and Animal Feed Ready Meals Snack Foods Sugar Starch and Yeast Water and other Non-Alcoholic Beverages |

| Max Throughput | 500 ppm |

| Camera Inspection Area | 360° Bottom Side Top |

| Inspection Solution | Checkweighing-Metal Detection-Vision |

| Max Product Width | 400 mm |

| Max Weighing Zones | 7 |

| HMI | 12" Touchscreen 15" Touchscreen |

| Packaging Type | Bags Bottle Bundles Cartons Cases Composite Cans Flow Packs Trays |

| Max Camera Field of View | 110 x 110 mm |

| Frequencies | up to 800 kHz |

| Label Quality Inspection | Graphical ID Label ID Label Placement Label Skew |

| Weighing Accuracy | from ±0.01 g |

| Label Data Inspection | 1D/2D Barcode Alpha Numeric |

| Max Product Weight | 10 kg |

| Max Line Speed | 180 m/min |

| Number of Reading Devices | 8 |