Innovation doesn't always mean adding something new; it can also mean eliminating the leading causes of problems. Solving the most common truck scale problem can result in dramatically more reliable weighing.

|

Historical service and repair data reveals the most frequent causes of vehicle scale downtime. Across makes and models, the leading causes of scale failures are junction boxes (also called summing boxes). These boxes are routinely opened to make adjustments to the scale. That exposes the sensitive electrical components and connections within to moisture and humidity, eventually causing errors and scale failures.

For decades, nearly every vehicle scale manufacturer has attempted to make better junction boxes. However, they still remain the leading cause of downtime, frustration and repair costs on vehicle scales.

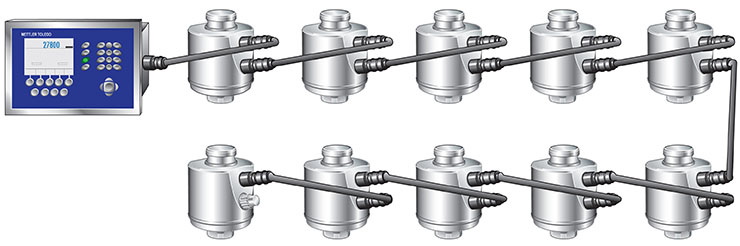

Only METTLER TOLEDO offers the POWERCELL® PDX® load-cell system as a permanent solution to this problem. Being the first vehicle scale load-cell system with no junction boxes, scales equipped with rugged and innovative POWERCELL PDX load cells provide dramatically improved reliability, even in the harshest environments.

Customers with POWERCELL PDX systems report fewer service calls and significantly reduced repair costs. Don’t wait for a junction box to result in your next repair bill. Whether you're interested in a new vehicle scale, or want to upgrade the scale you already own, request a quote for the permanent solution to frequent scale problems.