Counting Scales

Enhanced speed and accuracy with piece counting scales

Counting scales are scales that speed up productivity while ensuring final kit completeness and quality. Counting scales from METTLER TOLEDO are able to measure even the smallest pieces and parts with accuracy – to ensure every piece is accounted for. Counting scale solutions can also connect directly to a PLC for elimination of manual data entry, leading to cleaner data and better operational visibility.

Weighing System SPC215-111

The highest degree of miniaturization enables precision weighing applications where installation space is a premium.

Weighing Module WMF204C-L/IE

The WMF weigh modules offer a slim footprint with direct Industrial Ethernet connectivity for high-speed, multi-line applications.

Weigh module SPE404-C

The SPE weigh modules combine a fortified design with high-precision weighing performance and convenient modularity.

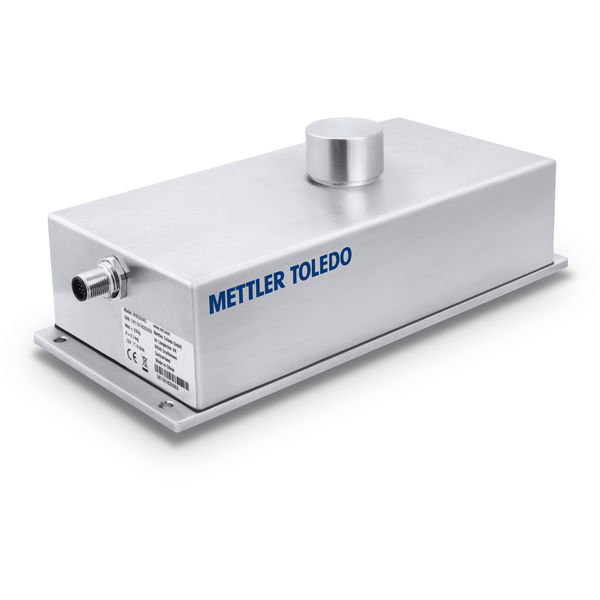

Weighing Module WKC6002C

The WKC weigh modules enable periodic onboard sample checks to ensure long-term process stability.

Unlock Service Excellence - Maximize Your Efficiency

Unlock Service Excellence - Maximize Your Efficiency

Explore our Services - Tailored to Fit your Equipment

Uptime. Support & Repair

Performance. Maintenance & Optimization

Compliance. Calibration & Quality

Expertise. Training & Consulting

- 100 lb Capacity Bench Scales

- Bench Scale with USB Interface

- Bench Scales

- Bench Scales 0.1g Readability

- Checkweigher Scales

- Dry Area Bench Scale / Dusty Area Bench Scale

- Industrial Basic Scales

- Legal-for-Trade Bench Scales

- NTEP Bench Scales

- Precision Bench Scale

- Printers and Peripherals

- Stainless-Steel Bench Scales

- Washdown Bench Scales / Waterproof Bench Scales

- Washdown Counting Scales / Waterproof Counting Scales

FAQs - Counting Scales

Industrial counting scales for any application

In industrial environments, mistakes and inaccurate information can be costly. Using a parts counting scale or count scale is a simple and fast way to determine the numbers of parts in receiving, warehousing, production or shipping, as you can see from the counting scales reviews for our industrial counting scales.

If parts are counted inaccurately, it can mean overfilling orders and therefore excessive costs, unstable production processes and a damaged reputation. Industrial counting scales calculate the weight of a group of uniform items placed on platform scales. A count scale or piece counting scale can then compute the average piece weight. They do so digitally by using a component called a strain gauge. A strain gauge can be used to measure the amount of force that is exerted on an object. An electronic counting scale can also take into account the tare weight, which is the weight of an empty container that may be holding the uniform parts. The electronic counting scale then subtracts the weight of the container from the overall weight of the goods.

Counting scales for highly accurate part counting

Discover a full line of parts counting scales offering a wide range of benefits. Some of the benefits of using a count scale include full barcode scanning and printing, a database configured to your specific needs, and full communication to your inventory/logistics planning and management systems. Sampling methods, operator messages and automatic accuracy improvements are user configurable as well. Counting scales typically are used in many industries, including the manufacturing and distribution of automotive parts, electronics, and plastic or metal components. The information from an electronic counting scale or piece counting scale can help reduce production costs. See for yourself from our counting scales reviews.

Counting scales or parts counting scales can be incorporated into inventory management systems to increase process reliability and productivity. But how do you determine which equipment is the best for your business? Looking at factors like your average capacity and minimum average piece weight will help you determine which scale best fits your needs. Several other key benefits and features may help determine the piece counting scale that will serve as the best partner in your manufacturing company by offering the ability to transact data to Excel for further statistical analysis and having available software to ease configuration and connectivity to external IT systems. A count scale application ensures accurate kits and happy customers, just check out our counting scales reviews!

We invite you to learn more about our electronic counting scales, industrial counting scales, and parts counting scales today. See what an electronic counting scale can do for your count scale application!