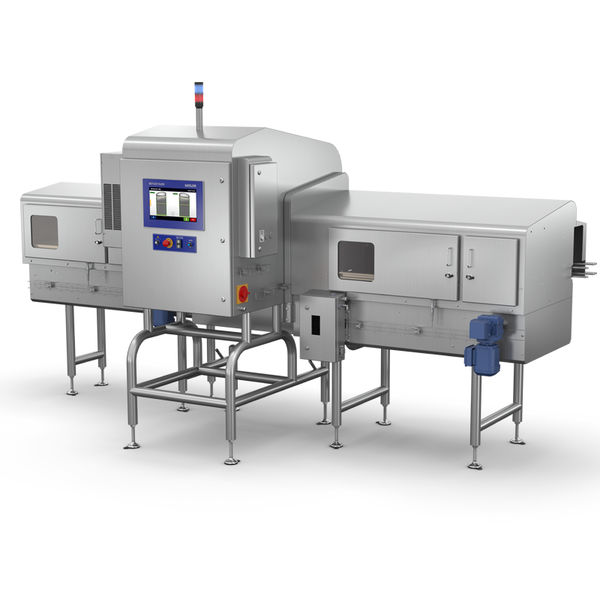

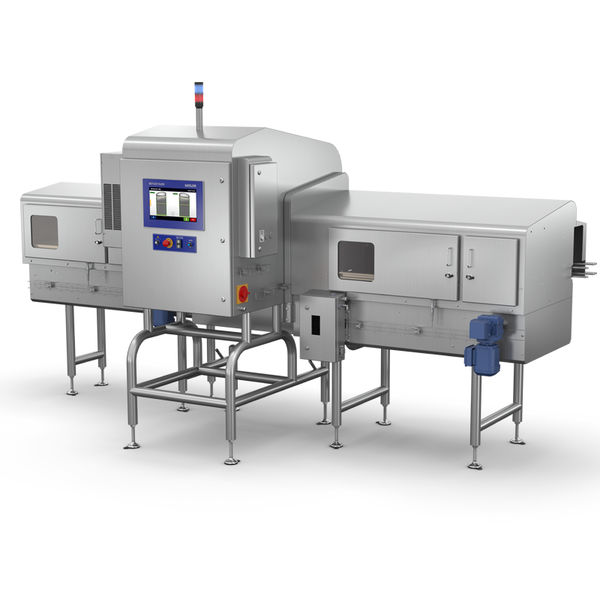

X37 Series – X3735

Achieving Optimum Inspection.The X3735 examines each product at two angles, thereby eliminating blind spots to ensure physical contamination detection and full integrity checks are completed at increased probability of detection (POD) levels.

Increasing Detection Sensitivity

The X3735's split beam increases the probability of detection of unwanted physical contaminants by imaging the product twice, thus minimizing blind spots.

Proving Due Diligence

All non-conforming products are removed from the production line and stored on a lockable reject table, accessible by authorized personnel only.

Enhancing OEE

Only authorized personnel can access statistics and inspection images, allowing for continual monitoring and reporting on manufacturing performance.

Material No.: 3054114700

Features

Specifications

Specifications - X37 Series – X3735

| IP Rating | IP65 IP69 |

| Compatible Software | ProdX |

| Connectivity | Ethernet OPC UA USB |

| Inspection Solution | X-ray Inspection |

| Max Product Width | 180 mm |

| HMI | 15.6" Touchscreen |

| Packaging Type | Cardboard Glass Metal Cans Metalized Film Plastic |

| Cooling Method | Air Conditioner & Radiator Pump |

| Product Flow | Conveyor |

| X-ray Beams | Split beam |

| X-ray Generator | 420 W, up to 84 kV, up to 5.0 mA Beryllium Tube 420 W, up to 84 kV, up to 5.0 mA Glass Tube |

| Inspection Application | Completeness Check Contamination Detection Fill level Check Integrity Check Mass Control Product-Trapped in Seal |

| Product Characteristic | Tall Rigid Containers |

| Industry | Chemical Food & Beverage Pharma & Biotech |

| Max Product Height | 330 mm |

| Industry Segment | Bakery and Confectionery Beer, Wine and Other Alcoholic Beverages Bulk Chemicals Cosmetics Dairy Fine and specialty chemicals Food Additives Meat & Poultry & Seafood Nutraceuticals Oils and Fats Pet Food and Animal Feed Pharma Ready Meals Snack Foods Sugar Starch and Yeast Water and other Non-Alcoholic Beverages |

| X-ray Detector | Single Energy, HiGain Technology |

| Max Product Weight | 30 kg |

| X-ray Emissions | < 1uSv/hr |

| Max Line Speed | 100 m/min |

| Max Throughput | 800 ppm |

| Diode Size | 0.8 mm |

Documentation

Datasheets

The X3735 x-ray system is a high detection sensitivity solution, with an integrated conveyor designed to inspect tall, rigid packaged products in a wi...