Checkweigher Systems

High performance weighing solutions for all industries

MID certified dynamic industrial conveyor checkweighing solutions offering inline quality control checks while helping manufacturers meet compliance with weights & measures regulations. Ideal for industries such as meat, poultry, and seafood, pharmaceutical, cosmetic, ready meal, bakery, baby food and more!

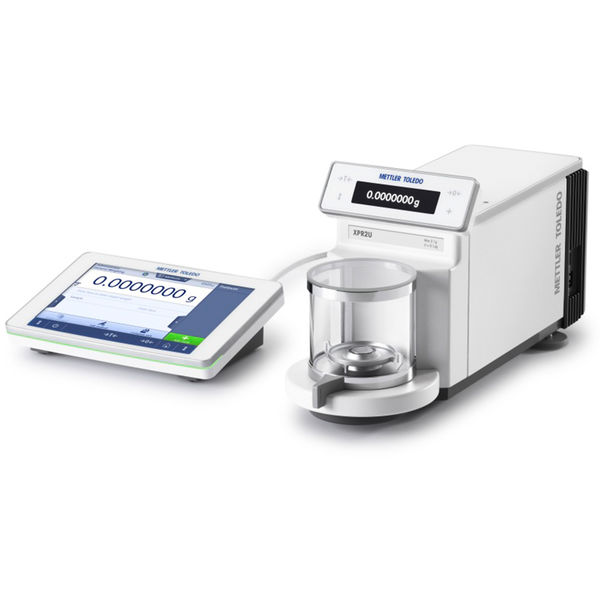

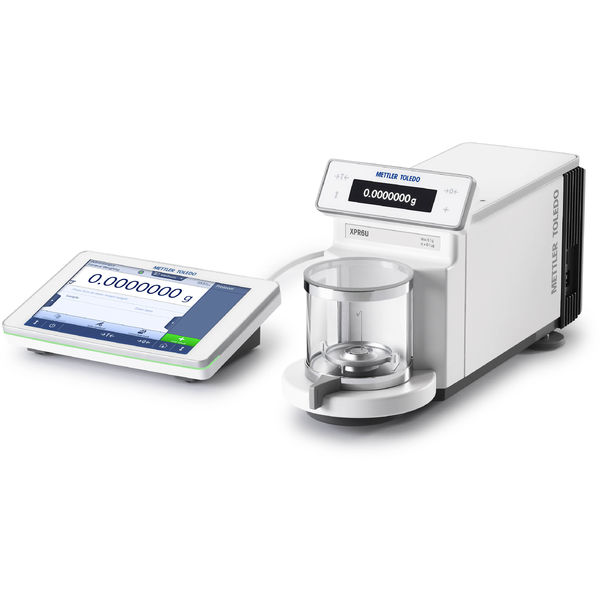

Balance XPR2U

마이크로 계량 한계까지 측정. 2.1g 용량 0.1 µg 해독도 통합적인 분석법 결과 노트패드 2개의 디스플레이 자동 드래프트 쉴드 완벽한 가시성 작은 설치 공간 손쉬운 세척 LabX 호환.

Balance XPR2UV

마이크로 계량 한계까지 측정. 2.1g 용량 0.1 µg 해독도 통합적인 분석법 결과 노트패드 2개의 디스플레이 자동 드래프트 쉴드 완벽한 가시성 작은 설치 공간 손쉬운 세척 LabX 호환.

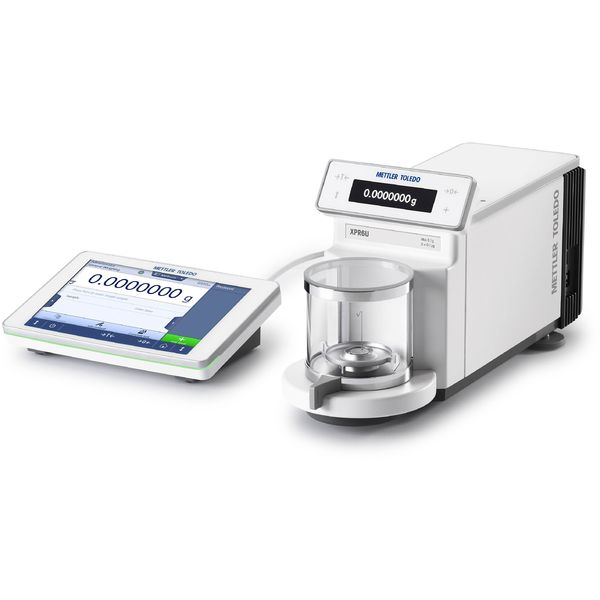

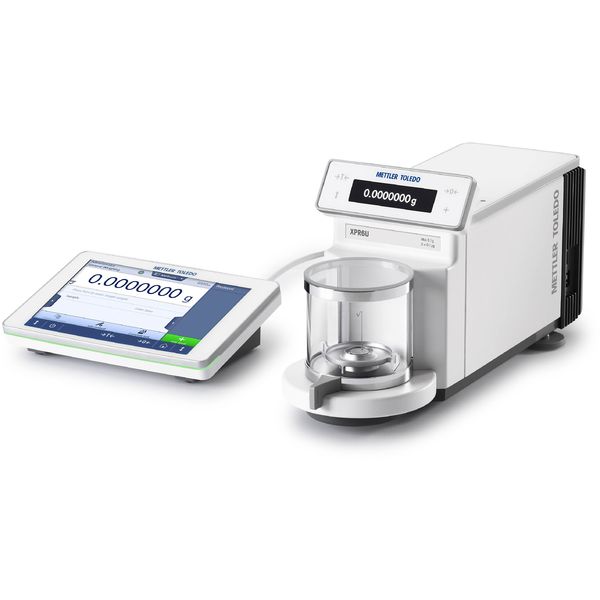

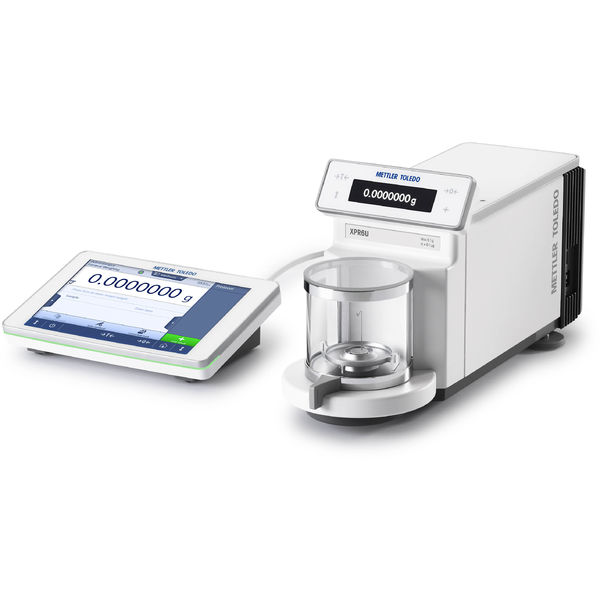

Comparator XPR6U

용량은 6.1g이고 해독도는 0.0001mg입니다. 주요 이점은 매우 정확한 질량 측정, 최소화된 계량 오류, 안전한 데이터 전송 및 매우 인체공학적인 작동입니다.

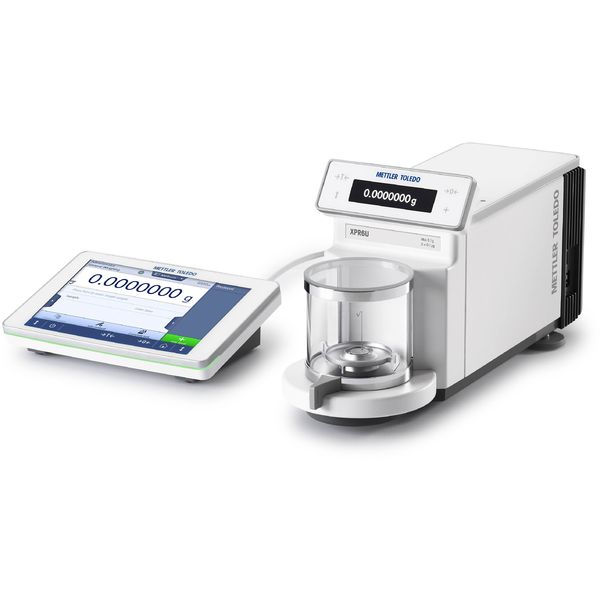

Comparator XPR6UV

Excellence XPR Ultra-Microbalance, 6.1g 용량, 0.1µg 해독도, Active Temperature Control 시스템 활용, GWP Approved 내장, SmartView 터미널 및 최신식 사용자 인터페이스.

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

Maximize Your Return on Investment by Ensuring Professional Installation and Right Care Package

New Remote Support

Keeping Your Production Running

In addition to our existing 24/7 technical phone support, we offer the latest in remote service support using Augmented Reality (AR) technology. This allows us to provide the quick expert support you need to achieve your productivity goals.

Our METTLER TOLEDO augmented reality-powered visual remote assistance solution helps us to fully understand your service issues. Using a mobile device with an integrated camera enables us to see exactly what you see. We can guide you step-by-step to resolve the issue by providing real-time contextual assistance, such as adding text, drawings, or highlighting objects with 3D markers. Benefit from the fastest fault diagnostics, repair, and part replacement support by using the latest technology. We can also remotely connect to some of our products for additional service enhancement. Please contact your local service team for more details.

Explore our Services

Uptime. Support & Repair

Performance. Maintenance & Optimization

Compliance. Calibration & Quality

Expertise. Training & Consulting

FAQs

What is a checkweigher?

A checkweigher is a high-precision weight measuring instrument, designed to check the weight of individual products, usually on a conveyor, on production lines during the manufacturing process.

Industrial checkweighers are predominantly used as part of a manufacturing quality control program. Using them in production facilities is often used to show compliance with local or global packaging laws and regulations.

An inline industrial checkweigher checks that each package is the correct weight as it moves through a production line. They are key to providing confidence that manufacturers are delivering quality products, promoting high levels of customer satisfaction. Selling underweight products can result in fines, recalls, or other penalties. Overweight products can generate unnecessary waste and expensive product giveaway. Industrial checkweighers can be used in most industries as part of an effective quality assurance system for:

- Food industry quality inspection

- Pharmaceuticals (pharma industry quality inspection)

- Cosmetics and personal care quality inspection

- Beverage industry quality inspection

- Transport / logistics

- Quality inspection of chemicals - including liquids, solids or powders

- Automotive

- Metal manufacturing and fabrication industries

What are the components of a checkweigher?

A typical checkweighing system is made up of:

- An infeed section (how the product is transferred to the checkweigher)

- A weighing section with weighing / load cell

- An outfeed section with sorting / rejecting device for products that don't meet pre-set specifications

- User interface for inputting specifications and checking results

- A solid and vibration minimizing frame - these can be built to stand up to a variety of environmental factors

There are many different checkweigher designs in common use. The components used to construct a checkweigher will vary in detail depending on how they are used. The characteristics of the items being weighed and their surrounding environment are also have a strong impact on the design.

What are the differences between a static and a dynamic checkweigher?

The main differences between static and dynamic checkweighers are:

- Static checkweighers measure the weight of products that stand still. Dynamic checkweighers weigh products in motion, on a checkweighing conveyor.

- Static checkweighers are used for manual weighing of products or for sample spot-checking. Dynamic checkweighers automatically check 100% of the products produced.

- Static checkweighing is a labor-intensive process. It requires manual product weighing, recording of the result and then product removal for the next weighing procedure. Dynamic checkweighing is entirely automatic. Products are weighed as they pass along a conveyor on a production line, with off-weight products rejected from the production line by automated removal devices such as pneumatic pusher arms or air-jets.

Static Checkweighers

- Bench scales, used for manual weight control and portioning of products or for sample-spot checking

- Designed to allow a fast and accurate weighing and portioning process

- Available in numerous variations and sizes for ergonomic working procedures

- Allow integration into data management systems for data tracking and analysis

- Fast and convenient label printing

Dynamic Checkweighers

- Weigh products in motion (i.e., checkweighers with conveyors)

- Automatically check the weight of 100% of the products

- Performing sample tests for net weight and tare weight reports that satisfy Weights & Measures compliance requirements and Weights & Measures package tare weight verification reports

Both static and dynamic checkweighers are to be found in most production environments, with static checkweighers commonly determining target weights for dynamic checkweighers.

The choice of type of checkweighing system used on a production line is usually determined by application requirements and processes.

Why should I use an inline industrial checkweigher in my production?

Industrial checkweighers have long been a key element of production operations, as they are capable of far more than just weighing, and can actually optimize your entire production process. Benefits of implementing an industrial checkweighing solution:

- Avoid costly fines with 100% weight inspection

- Keep fillers operating in synchronization

- Save on wasted materials, allowing for the production of more products, leading to higher profits

- Improve production processes and equipment efficiency

- Save labor and personnel costs

- Reduce false rejects and rework

- Maintain the identity of your brand

In addition, an industrial checkweigher can effectively improve your overall equipment efficiency (OEE) and thus reduce your total cost of ownership (TCO).

Which checkweigher manufacturer should I use?

METTLER TOLEDO offers standard and highly customized checkweighing solutions that are built to suit your specific applications and environment, as well as your regulatory and industry requirements.

We deliver productivity and profitability with our comprehensive line of checkweighers for food and beverages, checkweighers for pharmaceuticals, checkweighers for chemical products and checkweighing for other non-food industries.

A wide range of sizes and configurations (such as multi-lane checkweighers, different sorting and rejecting devices, and a variety of belt designs and product guiding systems) are available to handle nearly any container type or package design, even at high production rates, to provide accurate product delivery, reduced giveaway, and optimized production processes.

The innovative dashboard-style controls and intuitive multi-lingual operator interface make product set-up and changeover fast and error-free, to ensure maximum uptime and productivity. Optional harsh washdown design up to IP69k and integrated metal detection and x-ray technology complete the impressive features of the METTLER TOLEDO checkweighing product portfolio.

- Automated Checkweighers for Snacks and Confectionery

- Bakery Checkweighing for Quality Inspection

- C2 Series High-Load Checkweighers

- Checkweigher for Packed & Unpacked Food

- Checkweighers for Dairy Production

- Checkweighers for High / Heavy Loads

- Checkweighers for Pet Food

- Checkweighers for Ready Meals

- Cosmetics Checkweighers

- Dry Environment Checkweighers

- Dynamic Checkweighers

- Food Checkweighers

- Garvens Checkweighers

- Harsh Environment Checkweighers

- Hi-Speed Checkweighers

- High-Performance Checkweighers

- Hygienic Checkweighers

- In-Motion Checkweighers

- Inline Checkweighers

- IP69 Checkweighers

- Meat and Poultry Weight Control

- Pharmaceutical Checkweighers

- Precision Checkweighers

- Washdown Checkweighers